Drilling

Our Company, in cooperation with the United States-based manufacturer, Michael Byrne Manufacturing, offers vertical drilling and horizontal directional drilling (HDD) solutions. The Cradle Boring system is manufactured with state-of-the-art safety and control features. This machine is designed for pipeline work in the oil and gas industries, and it is capable of working in muddy, sandy and lose rock ground conditions. The machine is capable of installing steel casing pipe ranging from (10-56) inches (25-142 CM) in diameter over a medium of (90-100)m and casing sections of up to 120 feet (36.6)m can be installed in one pass to a cradle-borning system. This cradle-boring unit is suspended by a side boom allowing casing sections as long as 120’ to be installed in a single pass. The machine is powered by a 350 HP water-cooled CAT Diesel and develops 187,000 ft. lbs. of auger torque. A hydraulic 65-ton winch pulls the engine forward in the pit. The cradle machine design allows quicker setup and smaller pit design. A 3 chain vices hold the steel casing firmly in place. Michael Byrne clutch assembly and emergency stop switch ensure short driveline shut down in an emergency.

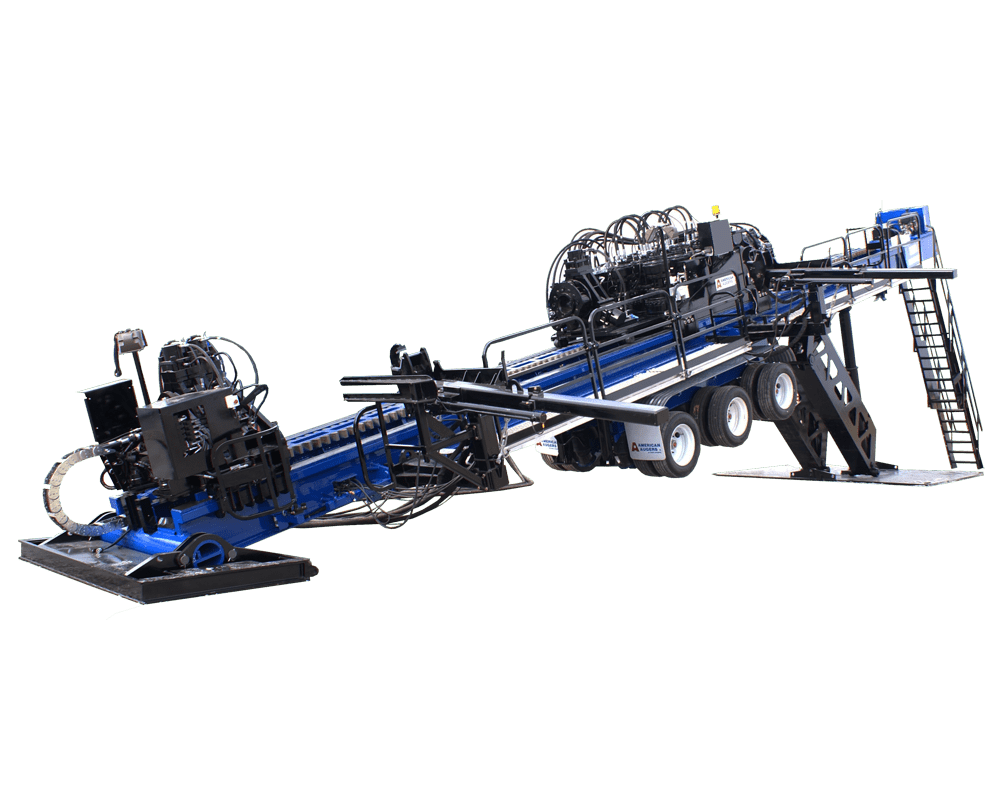

The Horizontal Directional Drilling (HDD) Machines comes from the United States-based Manufacturer, American Augers, offering state-of-the-art technology of heavy-duty HDD systems.

From their wide range of systems, the DD-1100RS comes as the first rapid setup system with up to 1,500 horsepower for the bores with a big pipe welded together, excellent speed, over 200,000 ft./lib breakout torque, and 4” drill fluid course accommodates up to 1,000 gpm of drill fluid for maximum fluid power.

The MCD-1000 is the Company’s first Derrick shaker cleaning system. With its actual 1000 gpm cleaning capacity of heavy fluid, four derrick shakers, and n-tank paddle agitation to keep solids from setting in the tank, makes it the game-changer for the industry and the way we all think about fluid cleaning systems.